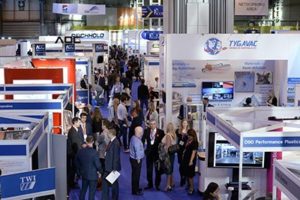

Advanced Engineering 2016 closed its doors last week to a record-breaking number of visitors, from all over the globe. Based both on the quality and quantity of visitors, the leading event of its kind also achieved its highest ever exhibitor rebooking for 2017.

Matthew Benyon, managing director at Artexis Easyfairs UK and Global, said: “The scale of Advanced Engineering is always particularly impressive and never ceases to amaze me. Once again we have seen fantastic numbers walk through the doors, but importantly, not only have we had quantity, but also the level of quality visitor has remained very strong this year. It also seems appropriate to say a massive thank you to all our show supporters, who have helped create such a wonderful atmosphere and allowed us to provide our visitors with access to the very latest trends and insights, from the industry’s best and brightest. We can’t wait to be back even bigger and stronger for 2017, so stay tuned.”

Speaking from the showfloor, Paul Hulse, business relations manager at Torkinton Engineers, said: “There is such a wide variety of products on show, it is fantastic. I am particularly interested in the 3D, advanced technology and future machinery, and there is loads on offer. It is also proving to be a fantastic networking opportunity. I just met with Network Rail, which I would never have had the opportunity to do if I wasn’t here. A real success story so far.”

Speaking from the showfloor, Paul Hulse, business relations manager at Torkinton Engineers, said: “There is such a wide variety of products on show, it is fantastic. I am particularly interested in the 3D, advanced technology and future machinery, and there is loads on offer. It is also proving to be a fantastic networking opportunity. I just met with Network Rail, which I would never have had the opportunity to do if I wasn’t here. A real success story so far.”

Innovation was present at every turn, with a whole raft of the exhibitors using Advanced Engineering to launch or demonstrate new products to the largest dedicated audience of buyers and key decision makers of its kind. This included UK Flowtechnik launching its range of Coriolis Flowmeters; Schneider Electric presenting its new Eurotherm Online Services; RamFoam debuting its new image based capturing technology; Composite Materials Italy displaying its new NANOALLOY® technology.

John Campton, key account manager at Premier Group commented: “It has been such a busy show. We normally come as a visitor, but made the change to exhibit, and we are glad we did. We are launching a new branch of our business, design for manufacture, part of the Premier Group and Advanced Engineering has proven to be the perfect place to do so. We have had lots of quality visits to our stand, and lots of meetings with potential partners about our long-term plans.”

Similarly, Nigel Peart, sales manager at FLIR Systems, agreed: “We exhibit at quite a few shows throughout the year, but Advanced Engineering is by far the biggest and best one we do. It is bigger in terms of visitors, quality visits to the stand and in terms of leads generated. We’re thrilled with the way it has gone.”

In addition to an increase in visitors and a packed exhibition hall, Advanced Engineering also hosted the largest open conference of its kind, providing visitors with over 180 hours of innovation case studies, supply chain opportunities, and market sector outlooks over the two-days. Visitors had the opportunity to learn from industry leaders including IMechE, SMMT, Rail Alliance, Magna International, Jaguar Land Rover, Airbus and Composites UK.

The conference programme covered a spectrum of hot industry topics from IIOT and the skills gap, through to human/robot interaction and reaching innovative SMEs. David Bailey, CEO at the North Aerospace Alliance, discussed ‘The productivity gap and Brexit Implications for the UK Aerospace supply chain’. During his talk Bailey stated: “In the last few months we have seen some important decisions being made, with Brexit right at the forefront of this. It is imperative that we retain our freedom of movement of employed labour even after we leave Europe. We need to sustain and protect our industry, and we can do this by working together. We will be more productive and successful if we have all of Europe working together on the aerospace sector, not separately.”

Also, speaking as part of the dedicated open conference was Richard Halstead, national interim membership engagement director of the EEF. Halstead presented ‘UK manufacturing, the big picture’ to a packed crowd, where he touched upon the apprenticeship Levy, Brexit and Industry 4.0.

Richard Halstead said: “The manufacturing industry is currently facing three big challenges. Firstly, we have the apprenticeship levy, which has been put in place by the government to help stop the skills gap from widening, but a worrying 41 percent of manufacturers say they are not going to change their approach. This is a very glass half empty kind of view. Secondly we have Brexit, which has battered UK confidence. We need to ensure we have global free trade, especially as 50 percent of UK exports are from the manufacturing industry. We need more reassurance from the government, just like the recent good news about Nissan. Finally, we are struggling to come to terms with connectivity and the 4th industrial revolution. 27 countries have set out ambitious advanced manufacturing targets, but the UK is not one of them. In fact, 67 percent of UK manufacturers have not even got a strategy in place. This is really worrying.”

The show also hosted a range of ‘features’ that demonstrated the innovative work of leading engineering professionals. These included Westfield Sport Concept, Bowler’s CSP, The Morgan V6 Roadster, Tesla’s low carbon vehicle, University of Wolverhampton’s F3 Car, Nikon’s robotic laser radar, Harper Adam’s University’s automated crop sprayer and the autogyro.

The next Advanced Engineering UK will take place on 1 & 2 November 2017. For anyone interested in exhibiting, more information can be found at www.advancedengineeringuk.com or via the show team on 020 8843 8800