The KALTENBACH Group of companies has announced two new cooperations with leading machine tool manufacturers ZEMAN and RSA, complementing their existing range of machinery for steel cutting and processing solutions.

For the UK market, the cooperation between Bedford based KALTENBACH LTD and RSA, who have offices in Telford, will mean that both companies are able to work together to promote a full range of circular sawing and deburring systems.

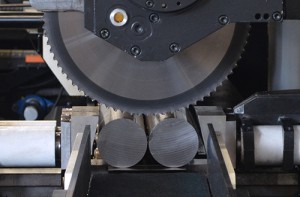

This combined range extends from RSA’s high quality, pull-down Haeberle saws through to KALTENBACH’S semi- and fully-automatic machinery and ultimately the high performance RSA billet and tube processing lines, including their well renowned tube deburring solutions.

RSA Machinery is highly proven across the worldwide metal cutting industry, particularly in high volume applications such as the automotive sector, where productivity, reliability and fast cycle times are paramount.

The latest RASACUT models demonstrate incredible performance. For example, during KALTENBACH’S IPS2015 exhibition during June, the RASACUT SH150-2 model was demonstrated simultaneously cutting 2x 100 mm diameter solid bars of ST-52 material in just 12 seconds.

The latest RASACUT models demonstrate incredible performance. For example, during KALTENBACH’S IPS2015 exhibition during June, the RASACUT SH150-2 model was demonstrated simultaneously cutting 2x 100 mm diameter solid bars of ST-52 material in just 12 seconds.

KALTENBACH Ltd also now cooperates with ZEMAN, the Austrian manufacturer of world leading solutions for steel fabrication and assembly. ZEMAN’S SBA (Steel Beam Assembler) range of machines represent a major leap forward in productivity potential when assembling the component elements of fabricated steel structures.

ZEMAN SBA systems use robotics for the welding and assembly work, with the range topping system able to automatically scan, pick and even reorientate fittings from a layout area and take them to the waiting steel beam for both tacking and final welding processes.

This approach virtually eliminates human intervention, automatically processing the final fabrication with full traceability and standards compliance. The systems achieve impressive and predictable performance with assured reliability from established robotic technologies, high build standards and software already well tested in the fabrication industry by ZEMAN themselves.

The ZEMAN product line also extends beyond welding solutions. The company additionally manufacture machine systems for producing items such as purlins and their ‘SinBeam’ steel beam design, which dramatically reduces section weight through the innovative use of a corrugated profile web in a fabricated steel beam.

KALTENBACH is well known for leading edge innovation in the steel processing industry and for machinery that achieves high levels of accuracy, repeatability and productivity. These are essential factors for the successful application of automated systems and the synergy between KALTENBACH and ZEMAN is a major advantage for those companies looking to invest in this new technology.

Alongside KALTENBACH LTD’S existing representation of ZINSER for steel plate profiling machinery and STIERLI-BIEGER for profile bending, straightening and rotation, the new partnerships permit it to offer solutions to many more industry sectors and a considerably enhanced portfolio to existing customers, in conjunction with their own comprehensive machinery range.

KALTENBACH Ltd

Tel: 01234 213201

Email: sales@kaltenbach.co.uk

www.kaltenbach.co.uk