Allied Machine announces GEN3SYS XT Pro Line of inserts and holders

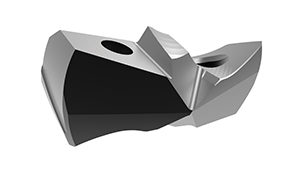

Allied Machine & Engineering, a leading manufacturer of holemaking and finishing tooling systems, has announced its new GEN3SYS® XT Pro line of high penetration drilling products. The product line features inserts and holders, designed with three unique geometries, as well as introducing two advanced coatings. Combining specific geometries and coatings to create the optimal solution for different machining materials, this next level of the GEN3SYS high penetration drilling product line delivers top results.

Allied Machine & Engineering, a leading manufacturer of holemaking and finishing tooling systems, has announced its new GEN3SYS® XT Pro line of high penetration drilling products. The product line features inserts and holders, designed with three unique geometries, as well as introducing two advanced coatings. Combining specific geometries and coatings to create the optimal solution for different machining materials, this next level of the GEN3SYS high penetration drilling product line delivers top results.

GEN3SYS XT Pro inserts have been designed specifically for ISO material classes, making tool selection easy. They are offered for steels (class P), cast irons (class K), and non-ferrous materials (class N). The drill inserts come in diameters ranging from 11 mm to 35 mm and are available in 0.1 mm increments. The inserts, designed specifically for steel and cast iron, have new AM400 series coatings, which provide increased wear resistance and tool life. Inserts for non-ferrous materials are coated with titanium nitride (TiN).

Holders for the GEN3SYS XT Pro line are offered in depth-to-diameter ratios of 3 x D, 5 x D, 7 x D, and a new 10 x D. These newly designed holders feature an enhanced flute design that improves chip evacuation and an updated coolant configuration that increases flow and directs additional coolant to the cutting zone. The GEN3SYS XT Pro holders are available in both imperial and metric shank diameters.

designed holders feature an enhanced flute design that improves chip evacuation and an updated coolant configuration that increases flow and directs additional coolant to the cutting zone. The GEN3SYS XT Pro holders are available in both imperial and metric shank diameters.

Allied Machine & Engineering devotes its advanced engineering and manufacturing capabilities to creating the widest selection of value-added tooling available to metal-cutting industries around the world. Its tooling solutions deliver the lowest cost-per-hole in a wide range of drilling, reaming, threading, boring, and burnishing applications.

Located in Kingswinford near Birmingham, Allied’s precision holemaking technologies provide end users worldwide with the highest level of drill performance. Precision engineering and expert application support make Allied the first and best choice for solving complex metal cutting challenges.

Allied Machine & Engineering

Tel: 01384 400900

Email: marketing.eu@alliedmachine.com

www.alliedmachine.com