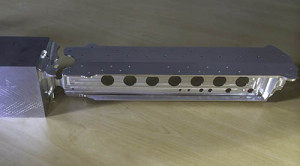

With a capability of maching in a single cycle complex components from up to 140 mm square bar stock, the Modig HHV-Bar machining centre offers significant productivity gains

RK International Machine Tools has entered into a five-year agreement with Aeromachinery Ltd to market the range of Modig machine tools. Sweden-based Modig Machine Tools is renowned for being a world leader in innovation and technology in the area of high speed machining. It is best known for its one-hit machining of aluminium aircraft stringers and its research into higher productivity and uptime performance in the aerospace industry is relentless.

Its latest developments include the Modig Extrusion machining centre. Designated the HHV, it provides a massive 50 percent productivity gain over earlier Modig Profileline machines, making it the most competitive processing machine in today’s market for machining Stringers or Longerons. The company has delivered more than 40 HHV’s over a four year period, many to customers placing multiple orders.

A further development of the HHV machine is its use on bar stock as opposed to extrusions. This new model features a heavier spindle and headstock. The key advantages of the Modig HHV-BAR machining centre are: a reduction in extrusion stockholding; the ability to machine similar designed components from bar; an entry into precision engineering sectors, such as electronics and medical components, while retaining the ability to machine in one cycle aerospace stringers.

RK International Machine Tools will focus on developing the market for the HHV-BAR machine within its existing customer base that encompasses businesses throughout the full spectrum of the UK precision engineering sector as well as OEM and Tier one aerospace manufacturing, and to identify new opportunities for this high-performance machining system.

Key features of the HHV Bar Mill are its ability to machine bar stock up to 140 mm square and 5000 mm long, four axes (X, Y, Z & U),  with 10m/s2 acceleration in all axes and accuracy of +/- 20 arc seconds on the rotary axis. The main spindle is a Fischer version B 30,000 revs/min HSK E63 unit, which is combined with a 24 position tool changer as standard. This combination of features results in cycle times between 40 and 60 percent faster,whilst the use of bar stock rather than billet reduces material use by as much as 30 percent and significantly reduces fixturing requirements.

with 10m/s2 acceleration in all axes and accuracy of +/- 20 arc seconds on the rotary axis. The main spindle is a Fischer version B 30,000 revs/min HSK E63 unit, which is combined with a 24 position tool changer as standard. This combination of features results in cycle times between 40 and 60 percent faster,whilst the use of bar stock rather than billet reduces material use by as much as 30 percent and significantly reduces fixturing requirements.

“RK International Machine Tools already supplies some of the UK’s leading aerospace companies with machines, both as off-the-shelf and turnkey solutions. With the UK having Europe’s largest aerospace customer base, generating £27.8 billion for the economy in 2013, the Modig range and notably the HHV series machines provide a great opportunity to further advance increases in machine productivity, through reduced component machining and handling times,” says Dick Aldrich, sales director, RK International Machine Tools.

The Modig HHV series is just part of a wide range of machining systems available from the Sweden-based machine tool builder, which specialises in providing solutions for the aerospace sector. The machines range from the Aeromill, with a capability of achieving metal removal rates of up to 850 cubic inches per minute to the Fleximill an innovative 6-axis machining centre for aluminum and composite components.

RK International Machine Tools Ltd

Tel: 01322 447611

Email: simonrood@rk-int.com

www.rk-int.com