Not resting on their laurels of being the 2015 British Formula 2 Powerboat champions, Team WNT F2 Racing is already developing its boat for the 2016 season, with new parts being designed and manufactured at WNT’s Sheffield Technical Centre, with the aim of reducing weight and, of course, increasing speed.

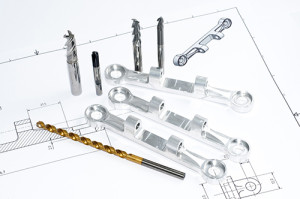

The new pulley components for the Team WNT F2 Racing Powerboat alongside some of the WNT tools used in their manufacture

The latest parts to be finished are new steering pulleys that have been designed from scratch. They reduce the weight of the original parts from 547 grams in the old assembly to 250 grams for the new assembly; a saving of almost 600 grams for the full complement of two pulleys. Some clever design work around the bearing housing also means that the pulley will not come into contact with the body of the boat and a clever pivot system ensures that the steering cable is directed to the drum in a much more controlled way adding to reliability.

“These small details are vital in a sport where you have to take advantage of every fraction of a second. We are achieving speeds in excess of 100 mph and making 180 degree turns on some courses, so anything that helps the boat change course smoother and quicker gives us an edge over our competitors. My sole aim for 2016 is to retain my British title. After that we may look at expanding our horizons,” says Team WNT F2 Racing driver Steve Hoult, who, when he is not racing powerboats, is the toolroom manager at Freudenberg Sealing Technologies, Automotive.

As part of the sponsorship package provided by WNT (UK) the team has access to the machine tools in the WNT Technical Centre as well as being able to call on the expertise of WNT’s project sales engineer, Tony Gale:

As part of the sponsorship package provided by WNT (UK) the team has access to the machine tools in the WNT Technical Centre as well as being able to call on the expertise of WNT’s project sales engineer, Tony Gale:

“We treat these projects for the powerboat team no differently than we would for a customer in that we look at all aspects of the job and develop the best tooling and workholding strategy to ensure the parts are machined to the exacting demands of the team. In this case we made use of a number of cutters from our new aluminium range as well as utilising tools from our specialist cutter range for titanium components.

“Workholding for the project was based around WNT’s Zero Point system, mixing in several sizes of vices from 40 mm through to 125 mm, with standard aluminium soft jaws and also specialist V-type jaws. The programs were created using Feature Cam software due to some of the complex forms required and then transferred to the XYZ VMC710 machining centre and XYZ CT52 turning centre for machining.

standard aluminium soft jaws and also specialist V-type jaws. The programs were created using Feature Cam software due to some of the complex forms required and then transferred to the XYZ VMC710 machining centre and XYZ CT52 turning centre for machining.

“Obviously winning the championship in 2015 was a fantastic achievement, but we recognise that  in our form of motorsport as well as any other if you stand still you go backwards, so developing new components, such as these steering pulleys, reducing weight and improving the overall performance of the boat is vital for our challenge in 2016. Having the latest in cutting tool and workholding available to us from WNT, along with their technical know-how, is invaluable in finding those extra seconds we will need to stay in front of our competition,” he concludes.

in our form of motorsport as well as any other if you stand still you go backwards, so developing new components, such as these steering pulleys, reducing weight and improving the overall performance of the boat is vital for our challenge in 2016. Having the latest in cutting tool and workholding available to us from WNT, along with their technical know-how, is invaluable in finding those extra seconds we will need to stay in front of our competition,” he concludes.

WNT (UK) Ltd

Tel: 0800 073 2 073

Email: tony.pennington@wnt.com

www.wnt.de/en-en